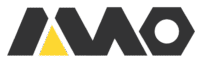

Shorbrace

Introduction

It can be used either with steel wailer 10, Double H20 Beam, or Aluminum Beam .

Due to high load capacity Shorbrace is one of the most economic system for heavy civil engineering project.

Shorbrace with prop extension is very flexible so one of the best system for building construction.

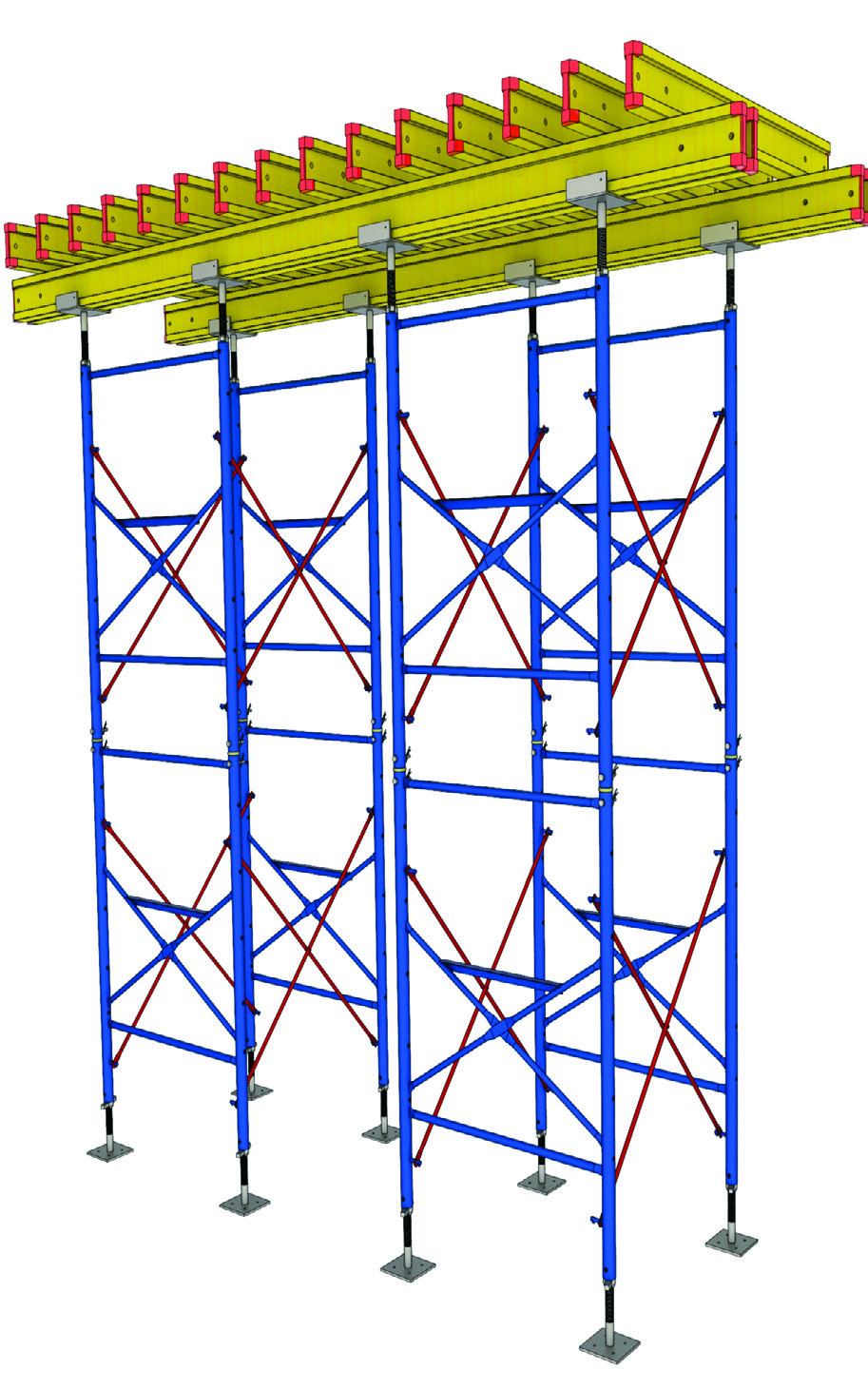

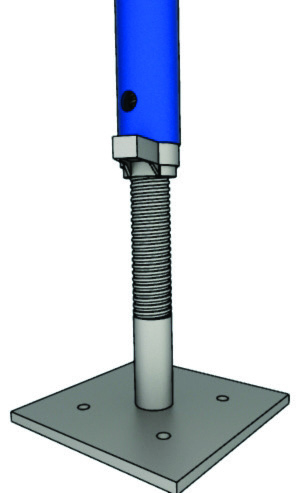

Vertically adjusting can be done either by post head jack in Shorbrace for heavy structure for building.

Advantages

- Shorbrace system is heavy duty.

- Variable heights can be obtained by using Shorbrace system .

- Shorbrace is limited components, Shorbrace System saves time

& effort. - It can be easily used in different projects.

- Being easy in erection & dismantling. Shorbrace system does not

need highly Professional labor.

Technical Data

- Safe Working load-capacity: 55 kN per leg, in accordance with AS3610

- Vertical tube are made from steel tube Q345 with Outer diameter 60mm.

- Shorbrace telescopic range is from 0.52 up to 1.42m

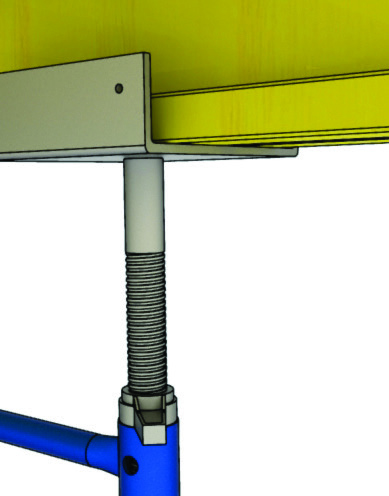

Shorebrace Frame

Shorbrace frame manufactured from steel tube with outer diameter 60.3mm with thickness 4.0mm. It’s braced by steel tube with outer diameter 43mm and thickness 2.0 mm .

Telescopic Frame

Shorbrace telescopic frame made of steel tube with outer diameter 48.3 mm with thick 4.00 mm, the telescopic frame give variable heights to shore brace system, it’s considered as coarse adjustment .

A cost-effective shoring tower for slab tables and high loads

- Simple and Robust.

- Great heights without any additional Scaffold Tube Bracing.

- High load capacity of standards.

- Large Dead Load efficiency-Carries up to 50 times of its own weight.

- Free standing and able to transfer the horizontal loads from wind.