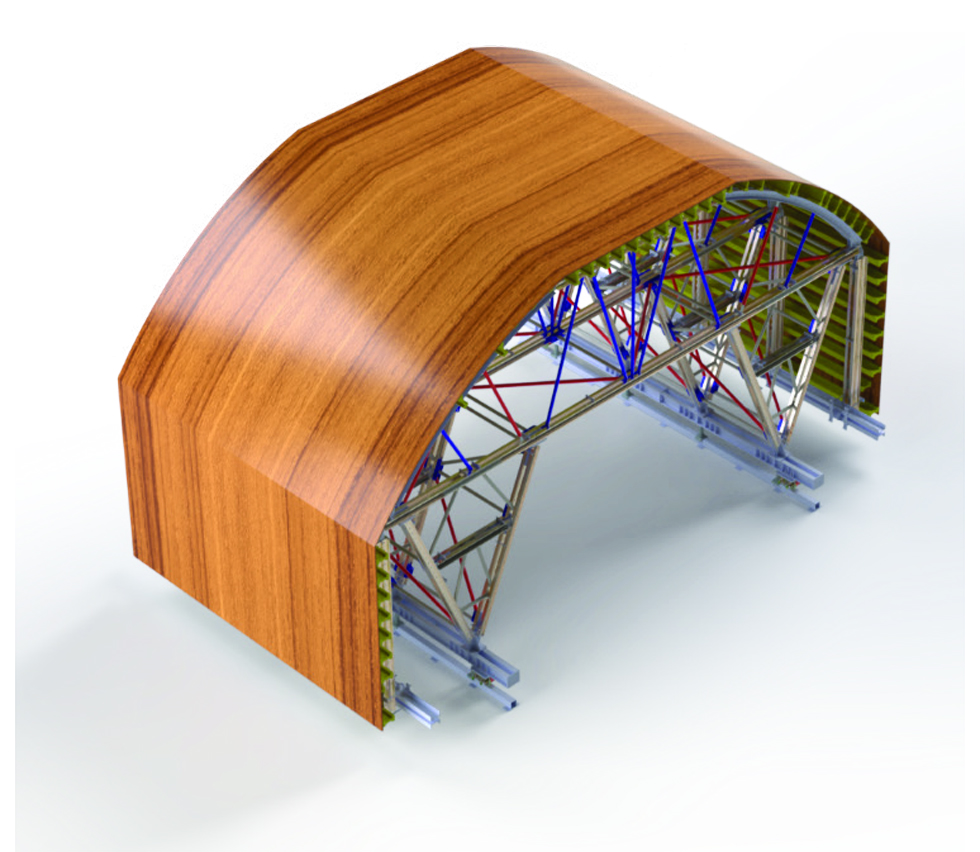

Tunnel Construction System

Tunnel Construction

Our comprehensive system offers flexible, cost-effective, and globally proven solutions for tunnel construction .

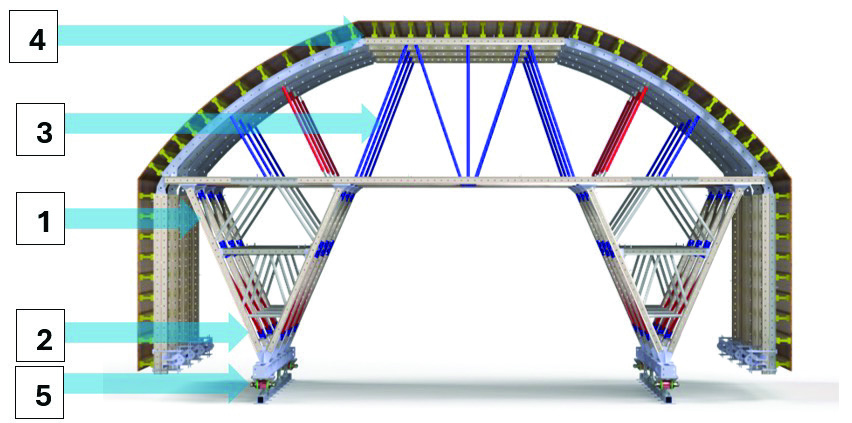

Tunnel Sub-Structures

1. Main structure.

2. Transport structure.

3. Bracing.

4. Formwork.

5. Rolling and levelling system.

Tailored Solutions for Different Tunnel Types Configurable Features:

1. Sections can be built in various shapes.

2. Structures can be configured for different pressures and loads.

3. Excellent concrete finishing is achieved.

4. Steel or phenolic panels can adapt to different tunnel radii.

5. Worksite access can be customized to meet project requirements.

6. Manual or hydraulic advance options are available.

7. Separate pouring of the side wall and vault is possible.

8. The distance between sections can be reduced to increase load-bearing capacity.

9. Easy stripping is achieved with screw jacks or cylinders.

10. Steel panels are reusable for use in other tunnels.

11. Panels include inspection windows and openings for pouring nozzles and vibrator support.

12. Multi-level platforms and access systems are available.

Applications

Suitable for both mining tunnels (e.g., subway stations, road and railway tunnels) and cut-and-cover tunnels.

Can be used for single-stage or two-stage construction (sidewalls and arch).

Key Advantages of Our System

1. Maximized ROI: Reusable, rentable components ensure long-term profitability across multiple projects.

2. Exceptional Flexibility & Strength: Modular design supports diverse structural configurations with high load capacity.

3. Fast & Efficient Workflow: Lightweight, integrated units eliminate disassembly during repositioning.

4. High-Quality Concrete Finish: Specialized steel or phenolic panels deliver smooth, radius-compliant surfaces.

5. Built-In Safety Features: Integrated platforms, stairs, and access systems ensure worker protection.

6. Customizable Configurations: Adaptable to various shapes, loads, and site access requirements.