Steel Waler

Introduction

The Steel Waler Formwork System is a versatile and robust system designed to accommodate a wide range of concrete forming applications. It is engineered to enhance operational efficiency and reduce overall project time and cost through its well-defined structural and functional features.

Maximum Concrete Pressure

The system is capable of withstanding concrete pressures up to 80 kN/m².

The spacing between the system elements is determined based on the actual concrete pressure requirements of the structure.

Concrete Surface Finish

The system allows the selection of various form-facing materials to achieve the desired surface finish, such as:

- Smooth fair-faced concrete

- Plywood surfaces

- Textured or patterned finishes

This flexibility enables the system to meet specific architectural and structural requirements.

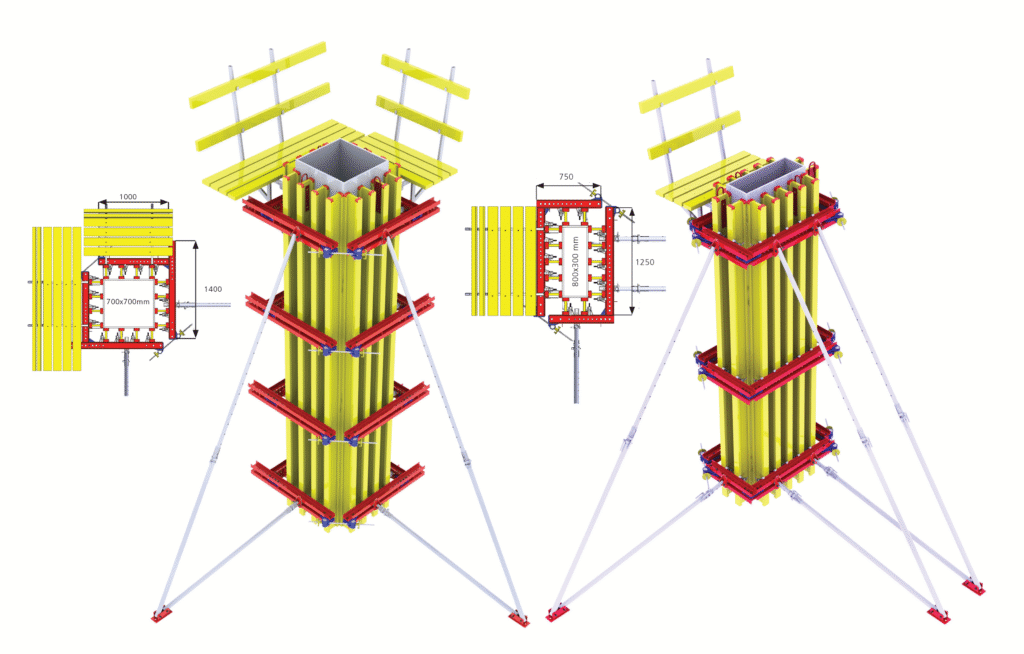

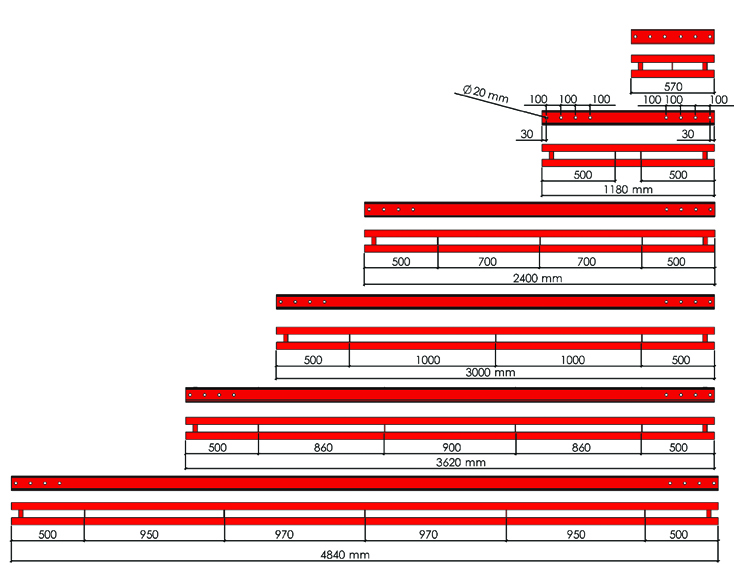

Wall and Column Dimensions

The system can be configured to accommodate a wide range of wall and column dimensions, ensuring precise alignment and surface quality according to project specifications.

System Handling

All components are designed for mechanical handling using cranes or lifting devices, significantly improving site productivity — particularly on large-scale construction projects.

Accessories

A comprehensive range of accessories is available to facilitate efficient and precise assembly, adjustment, and alignment on site, enhancing both safety and performance.

Assembly and Disassembly

The system is designed for rapid assembly and disassembly with a minimum number of components. This feature minimizes labor time and simplifies site operations.

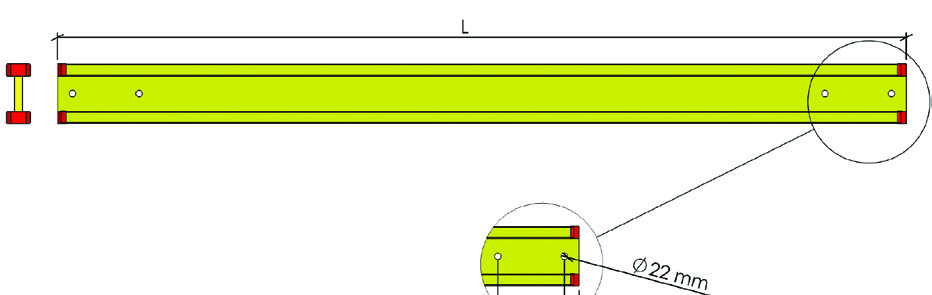

Panel Connection

Adjacent panels are securely connected using standard connectors and rivet pins, ensuring stability and alignment during concrete placement.

System Flexibility

The system’s modular design allows it to be configured according to:

- The required concrete pressure

- The size and geometry of columns and walls

- The desired surface texture and finish

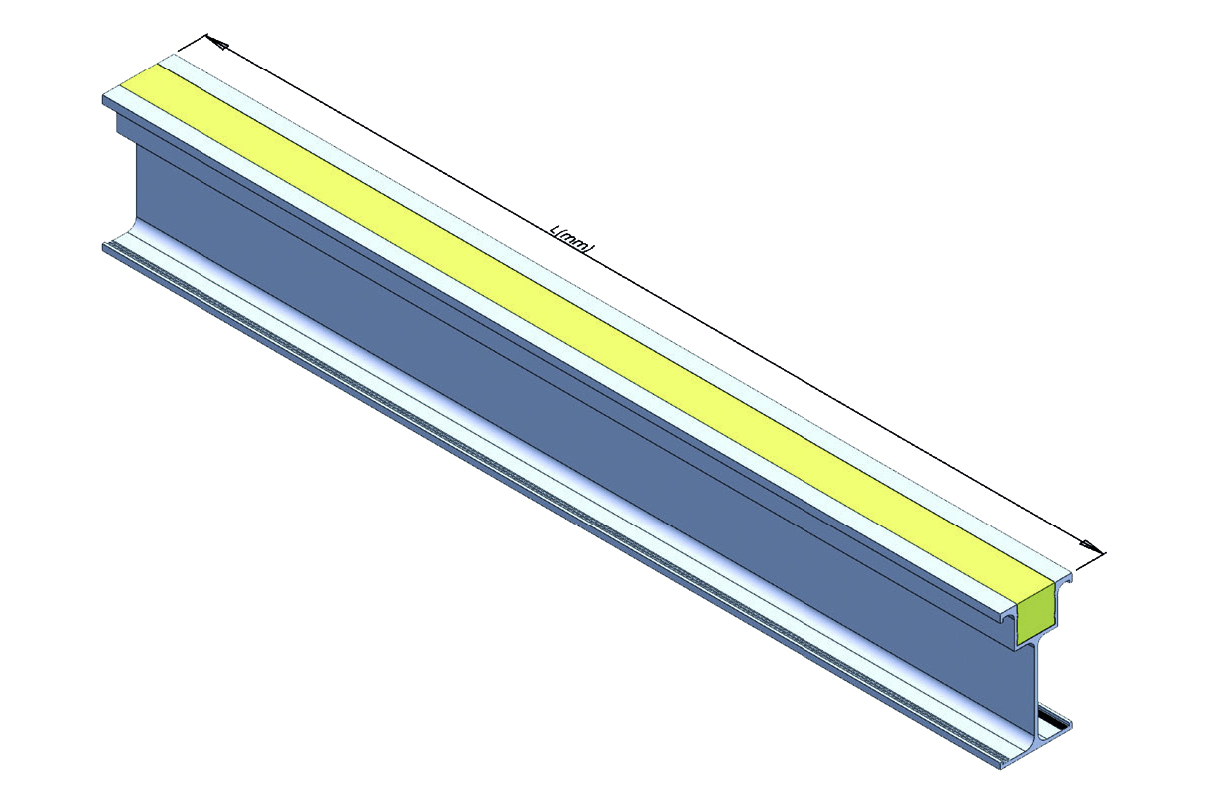

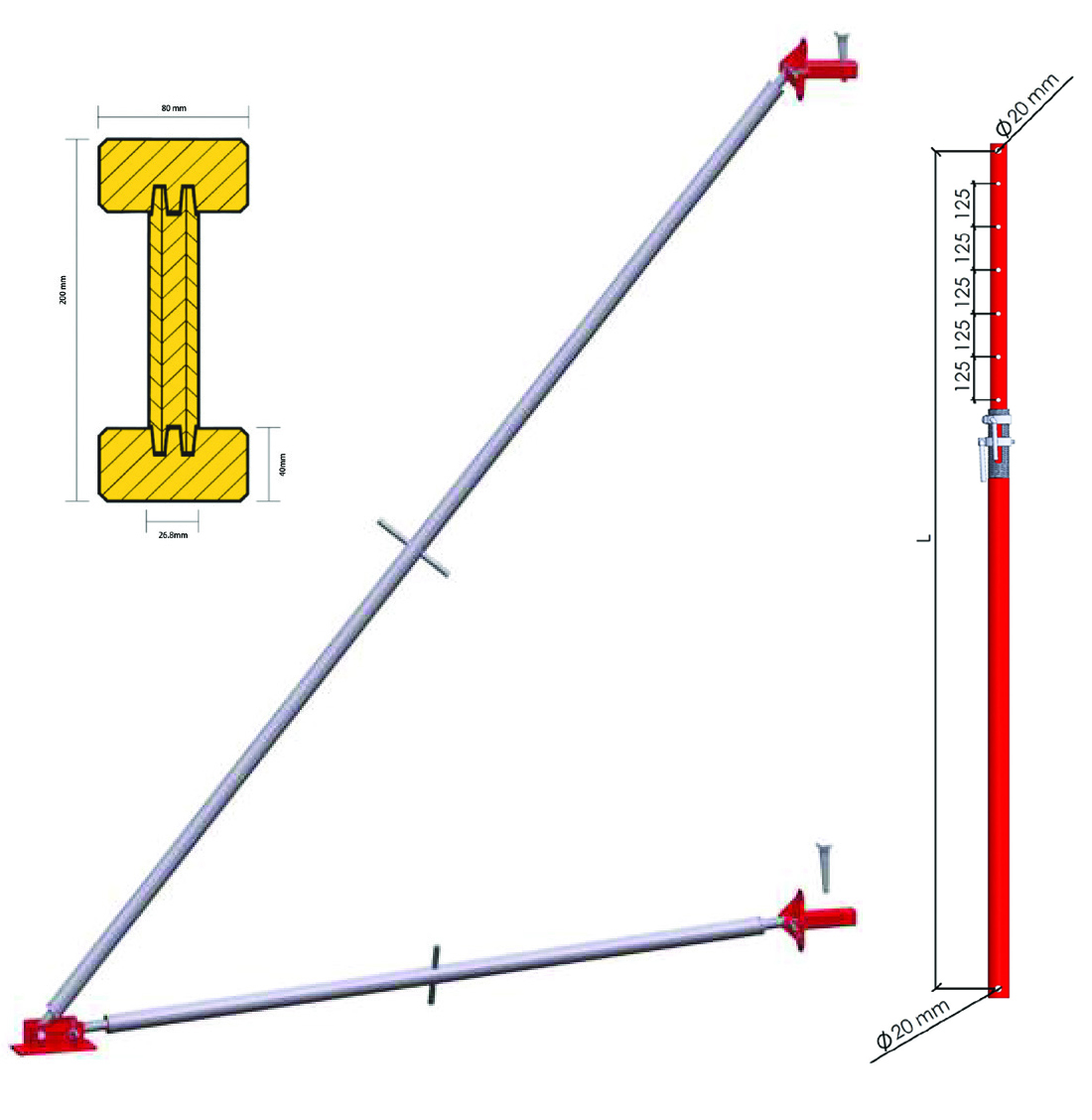

H20 Beams and Aluminum Beams

- For high-rigidity applications, the use of H20 timber beams is recommended.

- For lightweight and fast-handling systems, aluminum beams are preferred.